The Department of Materials focuses all trades and scientific and technical expertise for the development of new materials, from design (computer modeling, synthesis, ...) to manufacturing (formatting, machining, ...). This expertise, from upstream to downstream, developed in the service of defense, found many interesting applications for civilian activities, as well as large industrial SMEs.

Aeronautical and space systems are composed of high-tech materials subjected to severe environments and stresses.

The laboratory characterizes the thermal and mechanical behavior of these materials in extreme conditions of temperature and depression.

The Laboratory Expertises Chimiques & Physico-Chimiques (LECP) catactérises materials, mainly inorganic, to determine their chemical composition and some physicochemical properties

The properties validation and the understanding of physical and chemical properties (laser damage, mechanical properties, optical) are at the core of studies in the laboratory through metrology and modeling

The Department of Explosives designs, develops and manufactures pyrotechnic devices of French nuclear warheads.

Find the activities of the different laboratoirs DXPL by clicking on the links below:

- LBC : Laboratory 'Bureau d'études et Calculs' ;

- LCMO : Laboratory 'Caractérisation des Matériaux Organiques' ;

- LDDP : Laboratory 'Développement de Systèmes Pyrotechniques' ;

- LMCR : Laboratory 'Modélisation & Caractérisation Réactive' ;

- LRSP : Laboratory 'Réalisation des Systèmes Pyrotechniques' ;

- LSFD : Laboratory 'Synthèse, Formulation et Détection'.

The mechanical characterisation is carried out within the Laboratory for Mechanical Behaviour of Irradiated Materials (LCMI).

This activity includes mechanical tests on irradiated materials, numerical simulation, material constitutive equation identification and also comprehension of behaviour and damage processes

The Service de Recherches de Métallurgie Physique (SRMP), or The Section of Physical Metallurgy, is a part of the Department of Materials for Nuclear Energy at the Nuclear Energy Division of CEA (Commissariat à l’Energie Atomique, Atomic Energy Commission). Its main mission is to study the fundamental processes underpinning the science of nuclear materials.

The Speeds of generalized corrosion (uniform corrosion) of metals or alloys which are generally used in aqueous environment depend not only on the material/environment couple, but also on physical-chemical conditions (temperature, concentration of species in solution, fluid velocity,…).

The determination of chemical durability of concrete materials requires the acquisition of experimental data, the understanding and modelling of elementary mechanisms relative to the material hydratation, the chemical reactivity, transport properties and the mechanical impact.

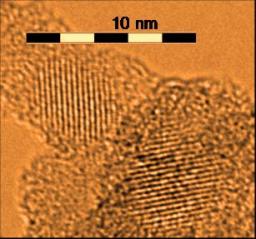

We study their growth process and their specific properties, especially those induced by size effects. By leveraging the diversity of objects that we synthesize(nanoparticles or carbon nanotubes), we develop nanomaterials and nanocomposites originals, here are some examples:

It is crucial, both at the fundamental level and the technology level, know design and build artificial surfaces able to interact with the external environment in a predefined way.

The Chemistry of Surfaces and Interfaces Group dedicates its activity in this area