About Minos

As the French leader for research on materials for nuclear applications, CEA launched the MINOS project (Materials Innovation for Nuclear Optimized Systems) in 2011.

This centre of excellence for nuclear materials was created by the Nuclear Energy Division (DEN) to promote, strengthen, and optimize research programs on materials used for nuclear power reactors and activities for the back end of the fuel cycle. It brings together all of the skills and means of DEN division dedicated to nuclear materials.

The objective is to find solutions for current and future nuclear challenges, such as: increasing the safety level, lifespan and availability of current reactors, optimizing the fuel cycle for current reactors, developing new materials for 4th generation reactors, and consolidating waste management policies.

MINOS consists of 720 staff members contributing to fundamental and applied research on nuclear materials in areas such as chemistry, physics, mechanics and behavior under irradiation. The research programs are guided by industrial needs, and MINOS sustains strategic research partnerships and innovative research programs for elaboration, characterization, design, physical understanding and modeling/simulation of nuclear materials (metals, alloys, ceramics, composites, glasses, concrete, bitumen, and geo-lolymers) and structures in extreme conditions.

|

>News/events

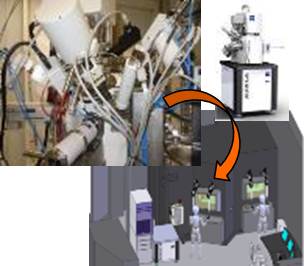

In the frame-work of the GENESIS French National Investment program, the LECI hot laboratory of the CEA Nuclear Materials Department, which is dedicated to the microstructural and mechanical characterization of irradiated materials, purchased a FIB to be nuclearized and, equipped with EBSD capabilities. This device, which is scheduled to be operational by the end of 2018, will allow the manufacture of nano samples for APT (Atom Probe Tomography) analysis of irradiated materials for microstructural and chemical studies at very small scales (10-9 - 10-10 m). The APT will be used to construct three-dimensional digital representations of samples with magnification up to 800,000x.

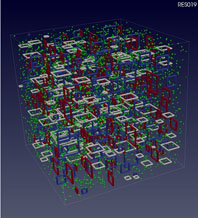

Comprehensive knowledge of the ageing of in-core and structural materials is critical to many of the challenges that we are currently facing, including the extension of the lifespan of current reactors, the development of new generation fast neutron reactors, and the continuous improvement of the safety of those systems. These endeavors require a multi-physics and multi-scale approach. An area of particular interest is the modeling of the population of radiation-induced defects and their impact on the mechanical plastic behavior of materials (stainless steels, zirconium alloys). As part of a recent project performed at the CEA Department of Nuclear Materials, the Cluster Dynamics code CRESCENDO (co-developed along with EDF) and the Dislocation Dynamics code NUMODIS (co-developed along with INRIA and CNRS) were chained within the MATIX_P numerical simulation platform. Based on the evolution of the radiation-induced defects computed with CRESCENDO, it is now possible to simulate the behavior of dislocations and their interactions with the defects using NUMODIS, and thus, to describe the micromechanical behavior of a metallic iron grain as a function of irradiation dose. The successful chaining of these codes will soon allow researchers to describe the multi-scale behavior of irradiated model and industrial materials.

> Highlights

Located in the Nuclear Materials Department at CEA Paris-Saclay, the JANNuS-Saclay irradiation facility generates ion beams with three coupled accelerators: Epimethee, Japet and Pandore. JANNuS is dedicated to the study of radiation effects in materials with the objective of experimentally simulating neutron-induced damage to microstructures. The new accelerator Pandore (PelletronÒ 2.5 MV, RF source with He, H, D, Ar beams) was recently commissioned. The dual-beam configuration with a high-flux iron ion beam generated by Epimethee and a helium beam provided by Pandore is of particular interest for studying mixed effects due to ballistic damage and a particles in PWR’s (reactor pressure vessel internals), fast reactors (reactor core cover plug, structures, absorbents) and fusion reactors (plasma-facing material, diverter).

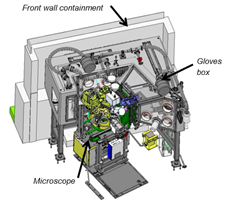

The Fuel Research Department of CEA Cadarache recently commissioned a new nuclear device for irradiated fuel characterization. This device consists of a SEM with a focused ion beam (FIB) and is equipped for many in situ techniques for 3D investigation and manufacture of samples at the microscale. Implemented in the LECA-STAR hot facility, it includes a specific containment system, various detectors dedicated to transmission imaging on thin films and crystallographic and chemical analyses, as well as a combination of in situ instruments (micro-manipulator, removable nano-indenter, STEM module). This new tool is dedicated to the characterization of fuel microstructure at the grain scale (a few µm) and the fabrication of nano-specimens for TEM observations of irradiated materials. It can be used to perform multistep machining with sequential imaging of specimen layers in order to reconstruct microstructures in 3D. It has already been used to investigate the fission gas bubbles of irradiated fuel (volume, pressure, structure). With its capacity to perform micro-mechanical tests, this cutting-edge equipment allows CEA to broaden its capabilities in the domain of irradiated fuel characterization.

>Agenda

Prospect of a new MINOS Workshop in 2019

|

Nuclearized FIB (Zeiss Auriga 40) and future lay-out in shielded cell at the LECI hot laboratory.

Image of an iron grain microstructure (0.4 µm in size) irradiated with neutrons in a reactor (27 days, 0.3 dpa), obtained with the NUMODIS Dislocation Dynamics code based on data generated by the Cluster Dynamics code CRESCENDO.

JANNuS-Saclay irradiation platform: the new PANDORE accelerator (Pelletron 2.5 MV) dedicated to ion implantations (He, H and D) in materials.

PLEIADES multi-scale simulation platform: pellet-cladding interaction (pellet cracking), microstructure (crystal plasticity mapping of fuel grains). |

Vous devez préciser l'id_ast dans la table des unités.